Optical Bonding A Key Technology for Enhancing LCD Display Performance

- What is Optical Bonding?

- Benefits of Optical Bonding

- Conclusion

In modern display technology, optical bonding has become a crucial process for improving the performance and user experience of LCD displays. By tightly bonding the display panel with a protective glass or touch layer, optical bonding enhances the visual quality and durability of the device. This blog will explain what optical bonding is and delve into its multiple benefits.

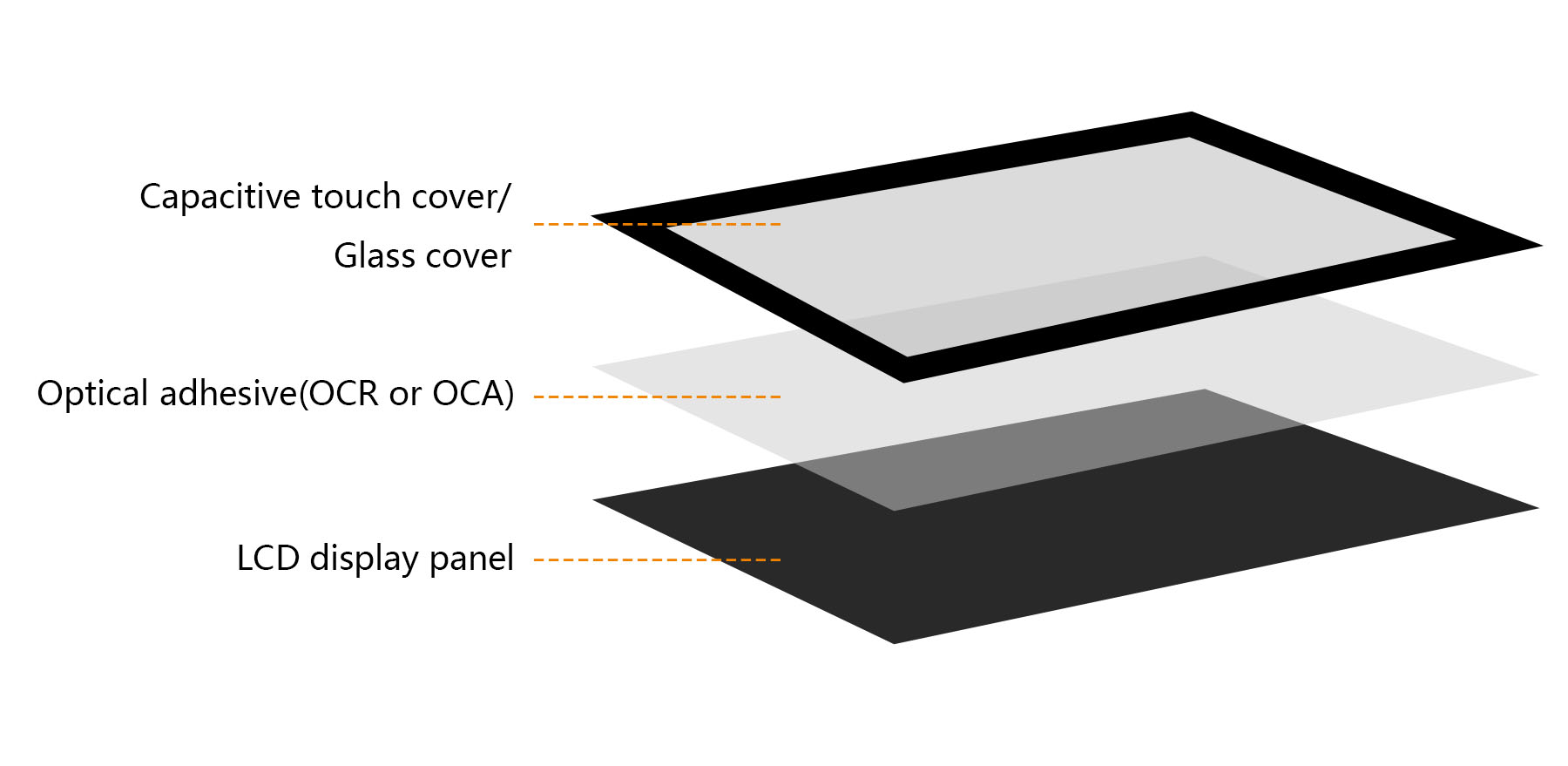

What is Optical Bonding?

Optical bonding is a process where a transparent adhesive, such as OCR (Optical Clear Resin) or OCA (Optical Clear Adhesive), is used to directly bond the LCD panel with the protective glass or touch cover. The aim is to eliminate the air gap between the two layers, reducing light reflection and enhancing the display’s visibility. Optical bonding is widely applied in outdoor LCD displays and other devices where high performance and durability are required.

Benefits of Optical Bonding

Optical bonding offers numerous advantages, significantly enhancing the performance and longevity of LCD digital signage and other display solutions.

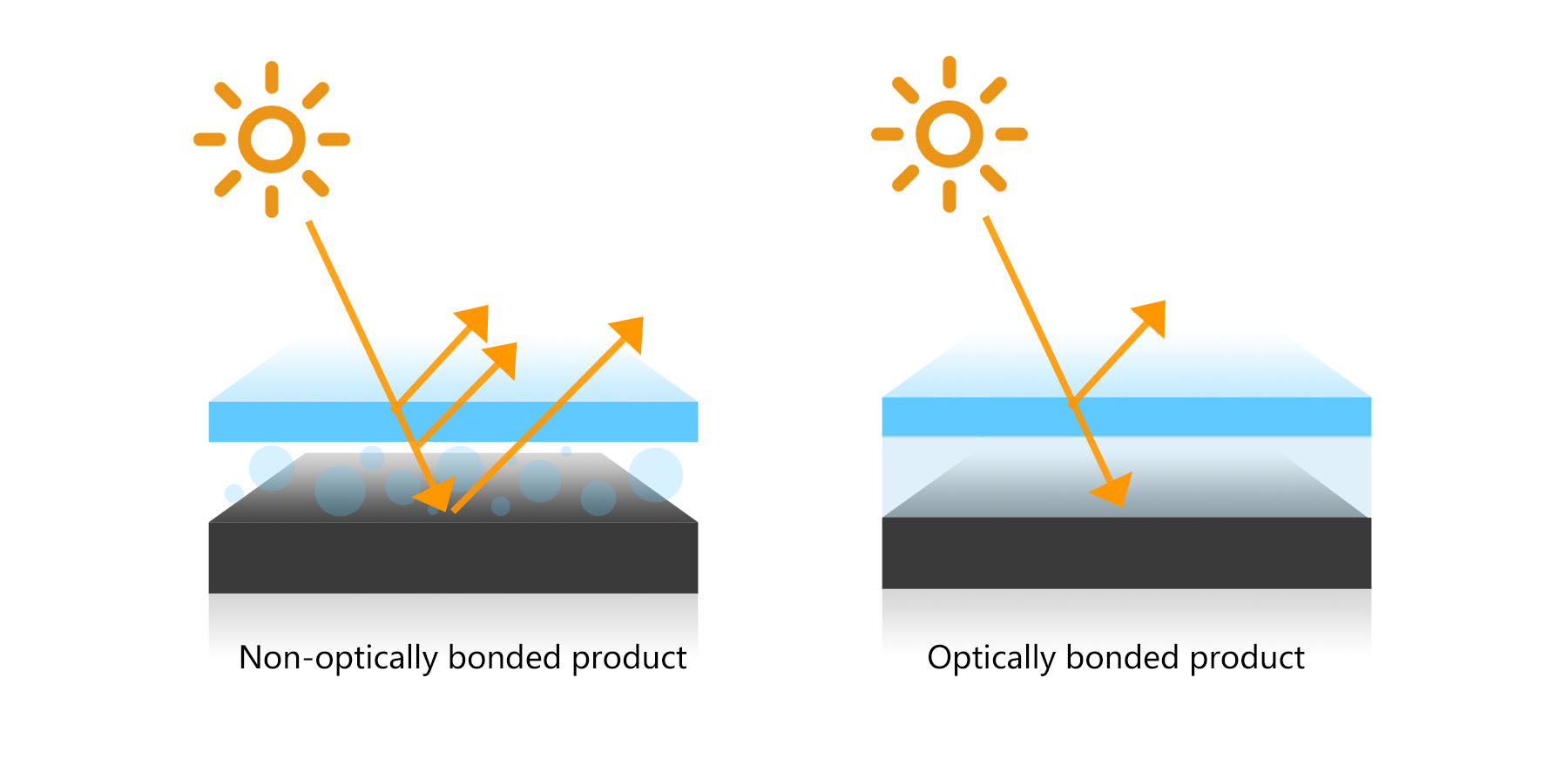

1. Reduces External Light Reflection

By eliminating the air gap between the LCD screen and the protective glass, optical bonding greatly reduces light reflection from external sources. This improves the contrast ratio and makes the screen easier to read, even in bright environments or direct sunlight. For outdoor LCD displays, this feature is particularly crucial for maintaining legibility.

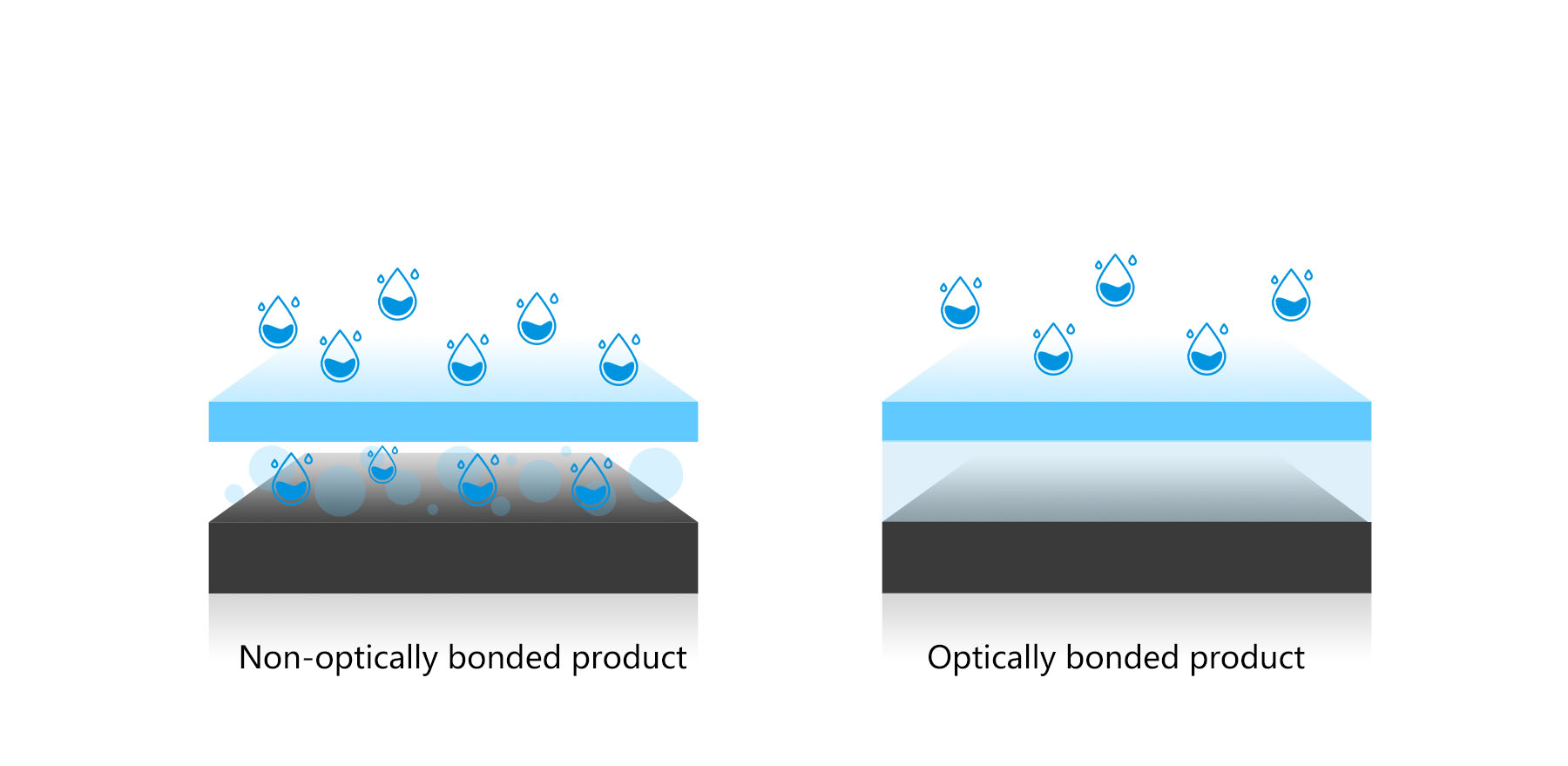

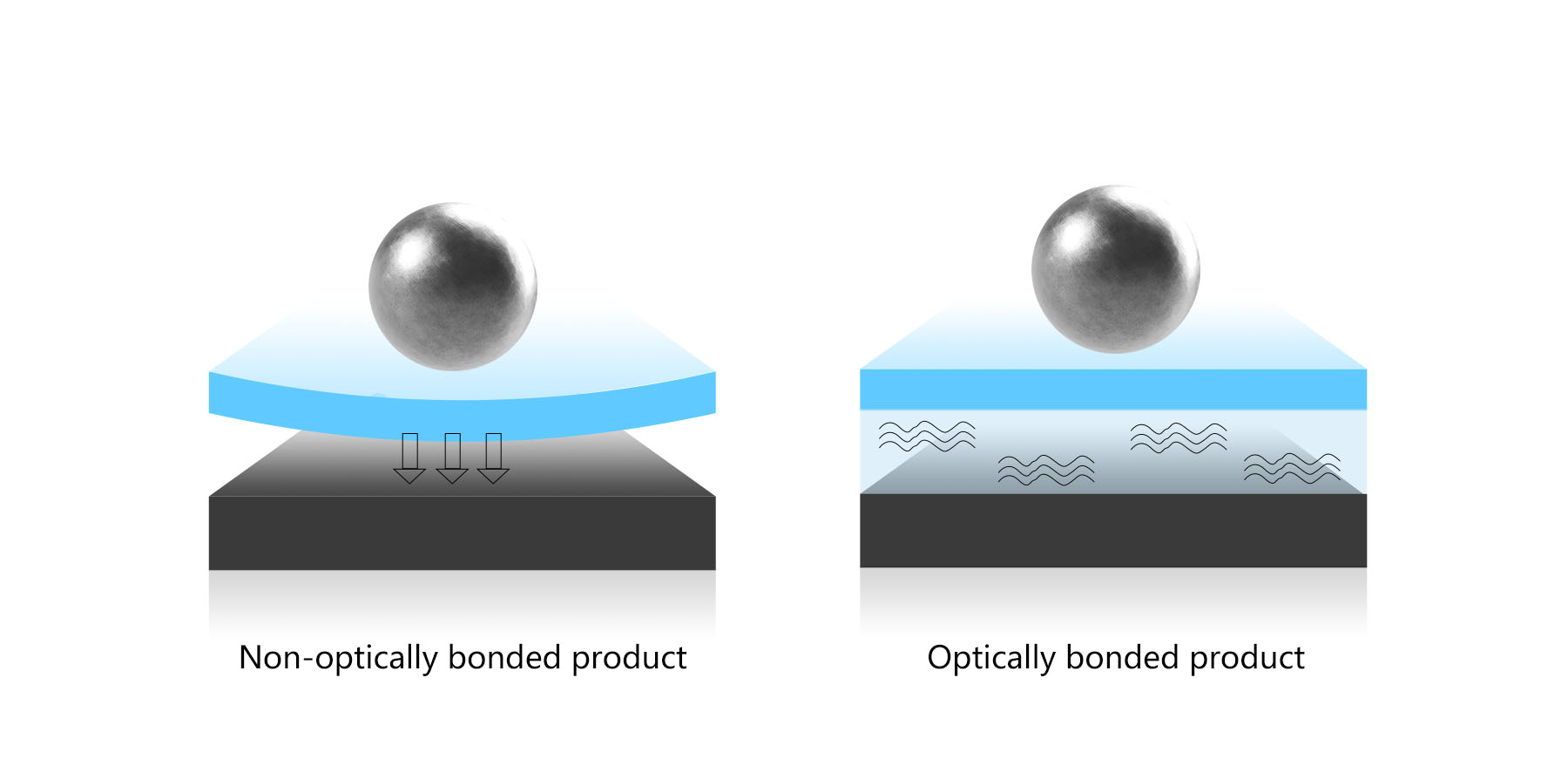

2. Prevents Condensation

In non-optically bonded displays, the air gap can lead to moisture buildup, especially in high humidity or rapidly changing temperature environments. This condensation can blur the screen or cause long-term damage. Optical bonding creates a sealed environment, preventing moisture from entering and thus stopping condensation from forming on the LCD display panel.

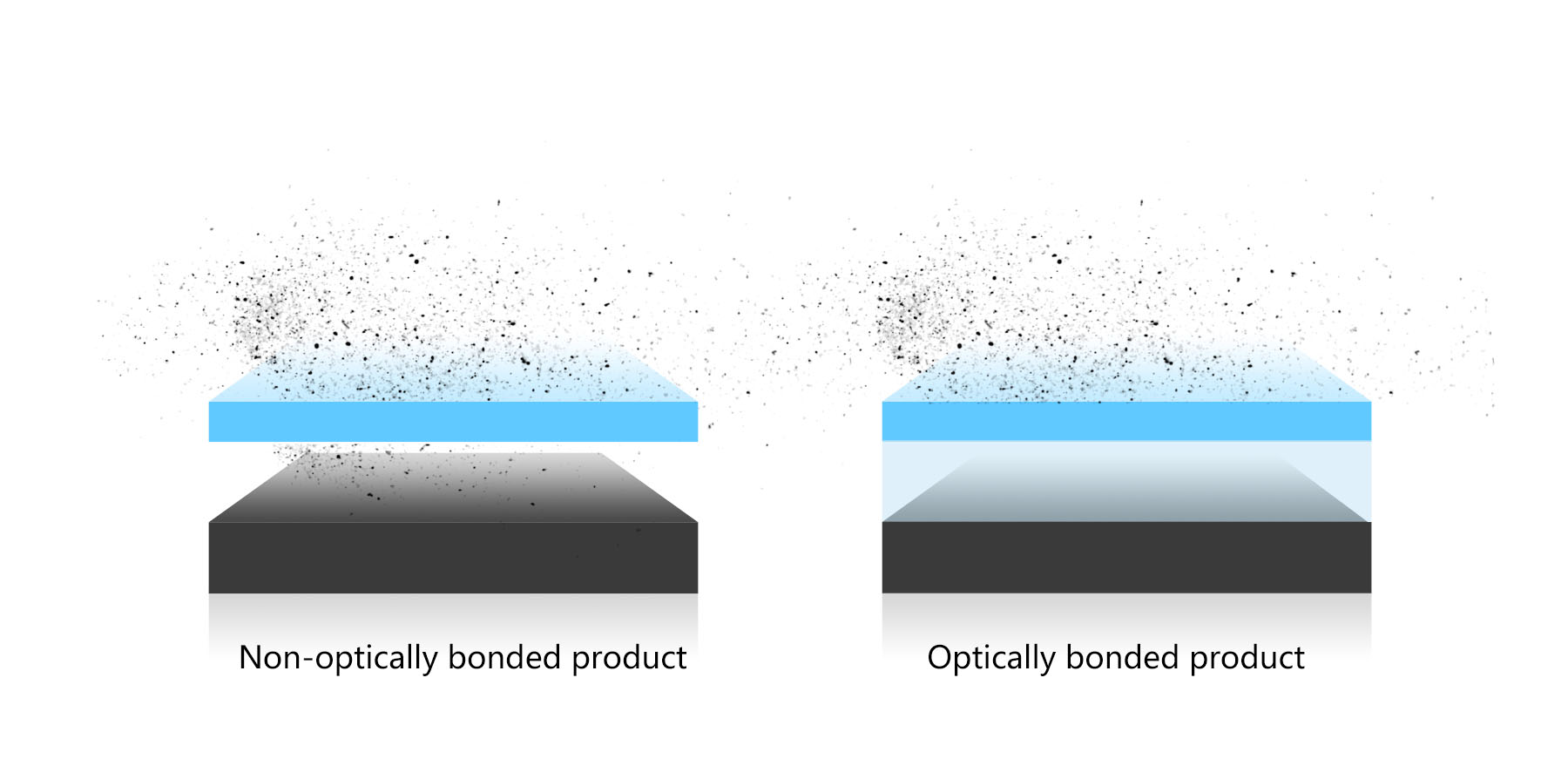

3. Prevents Foreign Object Infiltration

Optical bonding also helps prevent the intrusion of dust, particles, or other foreign objects into the gap between the LCD panel and the glass cover. This keeps the display clear and free from interference, prolonging the device's lifespan. In high-brightness LCD screens, any dust particles between the layers could significantly impact the clarity of the display, which optical bonding eliminates.

4. Enhances Impact Resistance

By tightly bonding the LCD display and the glass or capacitive touch cover, the screen becomes more resistant to impact and damage. This increased durability is especially important for outdoor digital signage, where the screens are subject to more frequent physical stress.

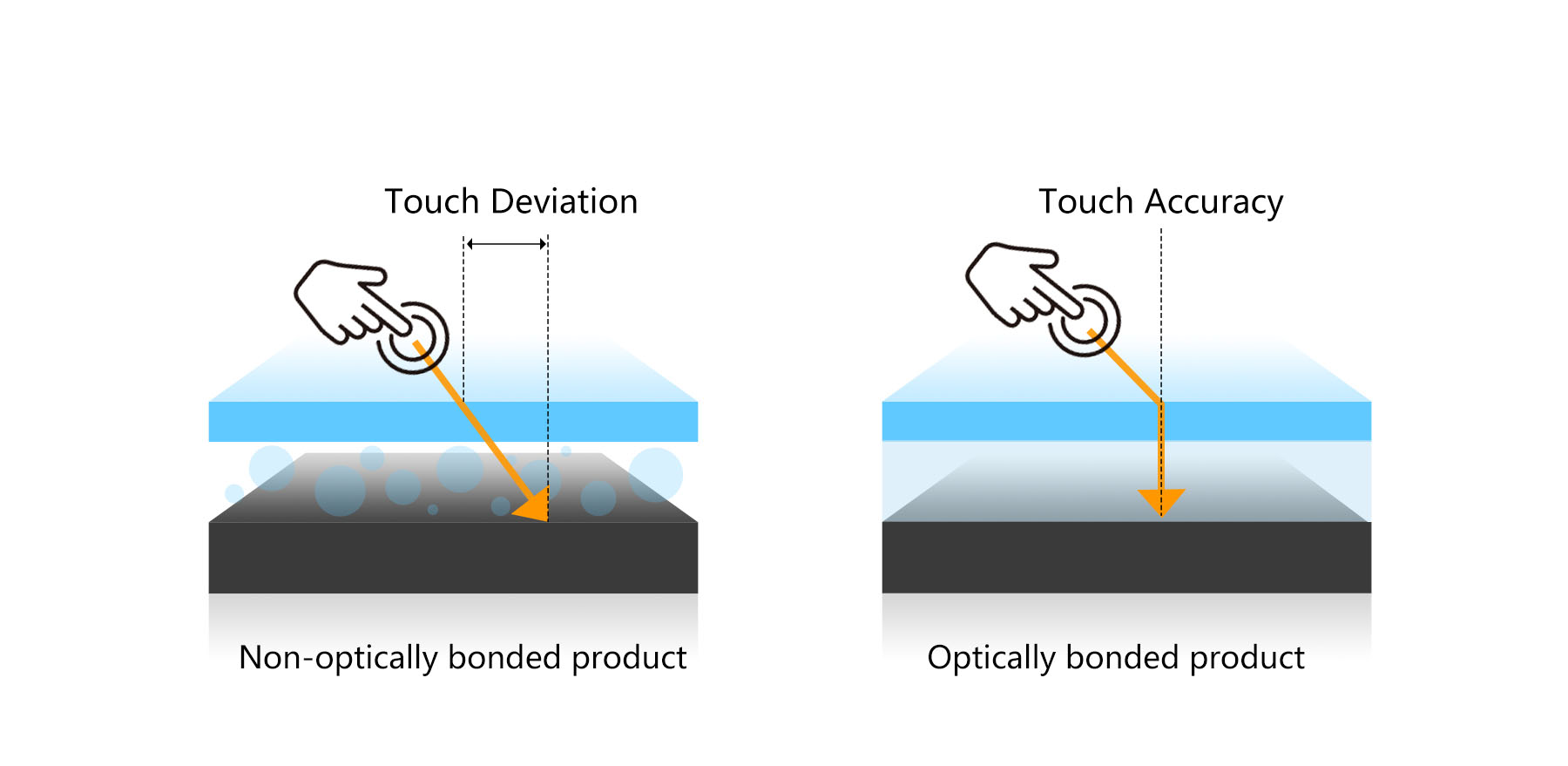

5. Improved Touchscreen Responsiveness

In capacitive touch displays, optical bonding not only improves the display’s visual clarity but also enhances its touch sensitivity. The elimination of the air gap allows touch signals to be transmitted more quickly and accurately, providing a more responsive and seamless user experience.

Conclusion

Optical bonding plays a pivotal role in improving the performance, durability, and usability of LCD displays. By reducing external light reflection, preventing condensation, keeping foreign objects out, enhancing impact resistance, and improving touchscreen responsiveness, this technology is essential for various applications, including outdoor digital signage and LCD digital signage. As the demand for high-performance LCD solutions continues to grow, optical bonding will remain a critical factor in delivering superior display technology.